Technology

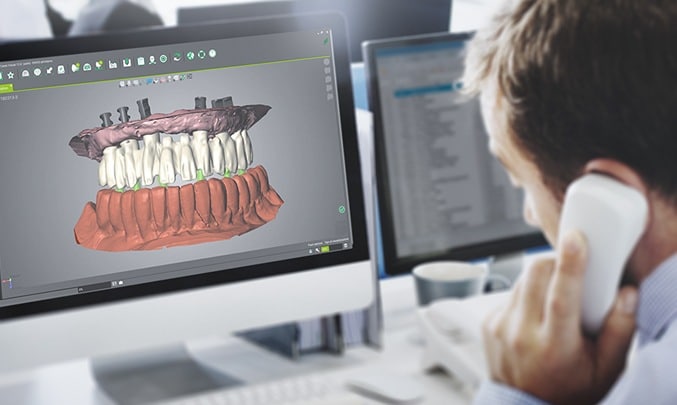

In the last twenty years in the field of dentistry we have witnessed a large degree of technological innovation that has revolutionized the concept of treatment plans for patients, bringing with it great benefits, above all in regard to prosthetic rehabilitation.

CAD/CAM technology has contributed to its own innovation, in pioneering fashion, and over time it has made its way, garnering the trust of clinicians and technicians.

The 3DSmileFactory makes use of completely digital technology and offers its clients a service capable of providing any prosthetic solution.

In the professional environment the use of such a system simplifies the manufacturing processes, creating benefits more and more appreciated by patients as well, who can profit from less invasive procedures, with a reduction in the number of appointments required and increased confidence in the work carried out by skilled professionals.

The CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems which take advantage of technology already in use for some time in the field of engineering, today enable its beneficial use also in the world of more advanced dentistry /dental technology, by means of manufacturing processes that undergo more oversight and are more easily reproduced, thanks to file storage.

From Analogue to Digital

The 3D Smile Factory laboratory has adopted the innovative Itaka system, which consists of Arthur and Cyclops.

Arthur is a dynamic articulator that replicates mandibular movements recorded in analog form with Cyclops.

Support

Within a professional context set up in this way, the fundamental requirement for its proper functioning is also based on the offer of continuous service and collaboration, a prerogative that the 3DSmileFactory puts in place to support the innovation CAD/CAM, distinguishing itself as a laboratory supported by a Call Center, manned by qualified personnel able to solve any problem encountered by clinicians or others, in the use of digital equipment and the use of materials.

Visite the page dedicated 3D Smile Factory Training

In support, we offer classroom training courses with specific equipment geared to dental technicians.

Quality Control

The 3DSmileFactory uses a protocol for every phase of the manufacturing process, thus guaranteeing a prosthetic product to meet every expectation.

A scrupulous protocol which above all provides an analysis of the medical order, containing all the information useful to create a medical device made for customers.

Punctual Delivery

The laboratory 3DSmileFactory is today already positioned as a precursor within the CAD/CAM system and is capable of satisfying the demands of its clients, making use of more channels.

A large part of the incoming workflow is based on the use of green technology, that is, the transmission of files from practices or laboratories.

We make use of the help of an internal courier service in the case of shorter distances, and of national courier services, for greater distances.

A service set up in this way becomes the indispensable adhesive for maintaining reliable and ongoing work relationships among the various interlocutors.